Construction and working Principle of Transformer

The transformer is a static device in its construction and the principle behind the working of transformer is Faraday’s law of Electromagnetic Induction. In this article, let us learn about the construction and working of transformers.

What is a transformer?

The transformer transfers the electrical power from one circuit to the other circuit without the change in frequency. The transfer happens based on the mutual induction between the two circuits that are linked by a magnetic flux.

A transformer has two inductive coils that are electrically separated from each other but are magnetically linked through a path for the flow of magnetic flux.

Transformers vary in different sizes and ranges. It ranges from small transformers used in the communication system to giant transformers used in the High voltage transmission system.

The output voltage of a transformer can be increased or decreased, with a proportional change in the current ratings. Accordingly, there are two types of transformers: Step up transformer and step down transformer.

In a step-up transformer, the input voltage is stepped up to a high output voltage. The number of turns in the primary coil is less than the secondary coil in the step-up transformer. When the output voltage is lower than the input side, it is called a step-down transformer. It has more turns in the primary coil than the secondary coil.

Based on the construction and application of a transformer, there are also several other types of transformers. It includes shell type transformer, core type transformer, power transformer, distribution transformer.

Construction of Transformer

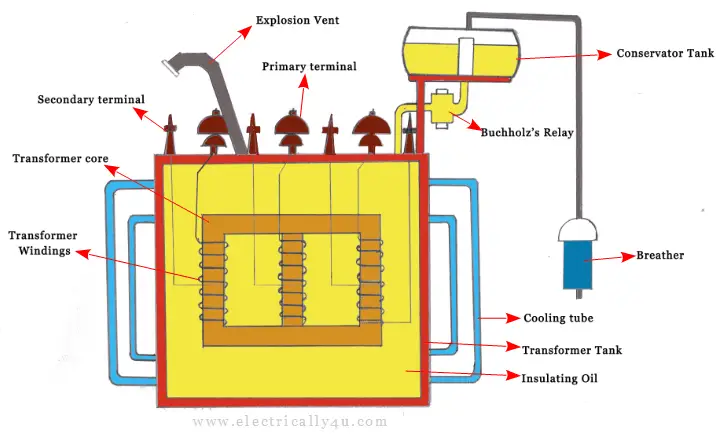

The construction of transformer is very simple for the small-sized transformer. It consists of a transformer core, primary and secondary windings. For a high range of power transformers, the core and windings are placed in a transformer tank with additional accessories.

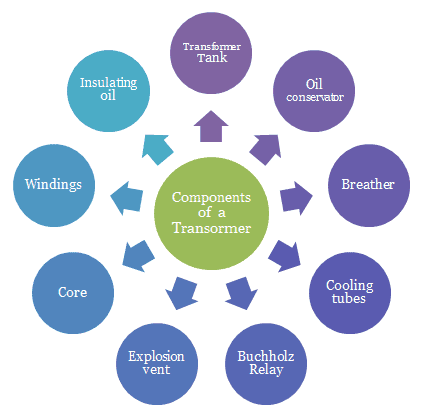

The main components involved in the construction of transformer are as follows

- Transformer core

- Primary and Secondary windings

- Insulating Oil

- Transformer tank

- Oil conservator

- Breather

- Cooling tubes

- Buchholz Relay

- Explosion Vent

Transformer Core

The transformer core is mainly used for two purposes: Provide mechanical support for the entire transformer and provide a path for the flow of magnetic flux.

The core is built up of soft iron or silicon steel laminations to provide a low reluctance path to the magnetic flux. The steel used should have high silicon content and be treated with heat to have better permeability and low hysteresis loss.

The laminations are insulated from each other by a coat of varnish or by an oxide layer. These laminations reduce the eddy current loss. The thickness of the laminations varies from 0.35 mm to 0.5 mm.

The laminations in the form of strips called stampings are joined together and pivoted to avoid any air gaps between the core. Various types of stampings like ‘E’ shaped, ‘I’ shaped, ‘L’ shaped and ‘U’ shaped stampings are used for the construction of transformer.

Based on the type of core used there are three types: core type transformer, shell-type transformer and Berry type transformer.

Windings

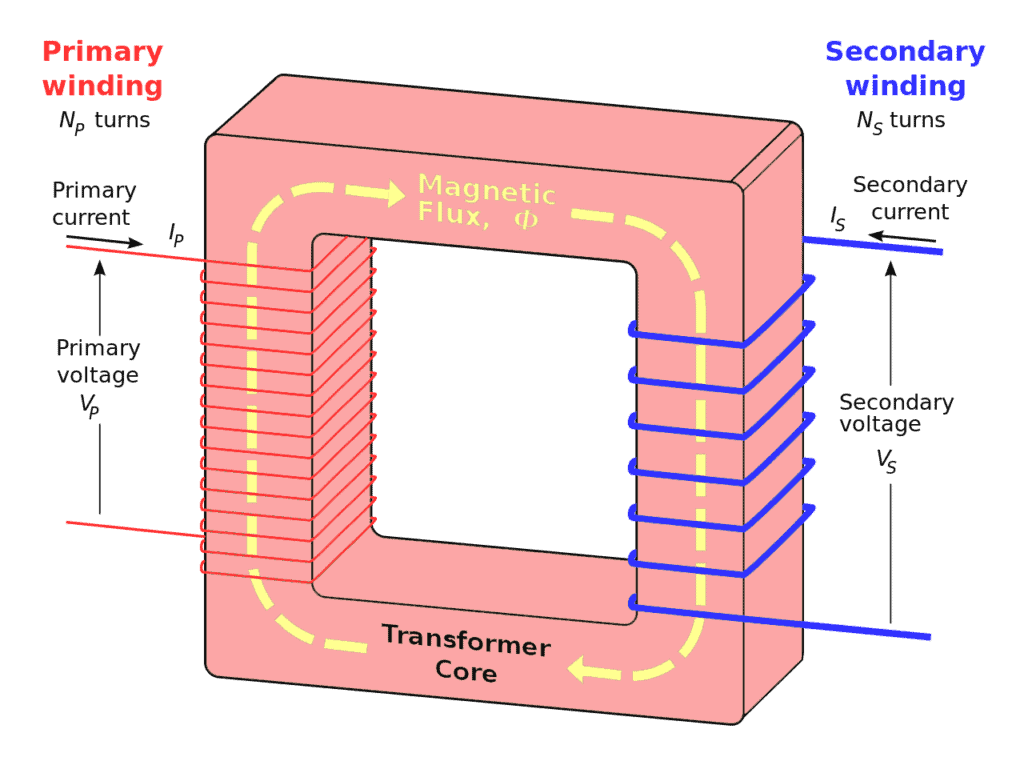

The transformer has two windings: primary winding and secondary winding. The primary winding is connected to the power supply and the secondary winding is connected to the load.

The winding connected to the high voltage circuit is called high voltage(HV) winding. The winding connected to the low voltage circuit is called low voltage(LV) winding.

The windings are wound over the core depending on the type of core used. In a core-type transformer, the windings are wound around the two legs of the core. In a shell-type transformer, the windings are wound on the central leg of the three-legged transformer core.

The windings are made of solid or stranded copper. Proper insulation is to be given to the windings to prevent it from short-circuiting. For huge power transformers, cloth or paper insulation is provided. Varnish coating is used as insulation for small-range transformers.

Transformer tank and insulating oil

The transformer core and winding arrangement are immersed in a tank containing insulating oil. The tank gives protection to the core and windings. Cooling tubes are welded with the tank for cooling purposes.

The insulating oil act as an insulation medium for core and windings. It is also used for absorbing the heat in the windings and core.

Oil conservator

The transformer tank is connected through a pipe to a small tank called the conservator. The Conservator is designed to act as a reservoir for the transformer oil.

An increase in temperature causes the oil in the transformer to expand. The conservator provides space for this expansion of the oil. The main function of the oil conservator is to keep the transformer tank completely filled with oil at all conditions.

Breather

Breather is a part of a large-sized transformer. During the change in temperature inside the tank, the oil expands and contracts.

For example, when the temperature goes down, it will make the oil to contract. So, atmospheric air gets absorbed inside a transformer tank. This process is similar to breathing in human beings and so-called as a breather.

Breather consists of silica gel, which prevents any atmospheric moisture from entering the tank from the outside world. All the moisture gets absorbed by the silica gel.

Cooling Tubes

The heat is produced in the windings and core due to copper loss in the conductors, hysteresis and eddy current loss in the transformer core. This heat has to be dissipated to operate the transformer efficiently.

The cooling tubes are used to remove the heat from the transformer oil and tank. Through this cooling tube, coolants in the form of oil or air are passed inside a transformer. The cooling method may be natural or forced cooling, which depends on the size of a transformer.

Buchholz Relay

Buchholz Relay is an important part of the construction of transformer. Buchholz Relay is a device used to protect the transformer from faults occurring inside the tank. It is a gas and oil actuated relay. The relay is placed between the transformer tank and the conservator.

Whenever a fault like a failure of insulation or damage to the core takes place, it results in the production of excess heat. This heat will decompose the oil and produce bubbles. These bubbles flow in the upward direction towards the conservator and get collected in the relay. The production of bubbles depends on the intensity of faults.

The bubble thus produced inside a transformer tank will activate the relay and give an alarm signal, indicating that there was a fault inside the tank. This will enable the operating person to disconnect the supply to the transformer.

Explosion vent

The transformer has an explosion vent to prevent any damage to the transformer tank caused by the excessive pressure generated inside the transformer.

If an explosion occurs in a transformer due to an internal fault, then the blast of the explosion will be allowed to escape through the explosion vent, rather than causing the transformer’s tank to explode.

Working Principle of Transformer

The Transformer works on the principle of Faraday’s Law of Electromagnetic Induction. When the primary winding is connected to the AC supply, a current starts to flow through the primary winding.

Since this winding is linked to the magnetic core, the current through the primary coil produces an alternating flux Φ in the core. Since this flux is alternating in nature and it is also linked with the secondary winding, so a mutually induced emf is induced in the secondary coil.

When a load is connected to the secondary winding, a current starts to flow in the winding. Thus the energy is transferred from the primary to the secondary side by means of electromagnetic induction. This transfer is achieved without the change in frequency.

The flux Φ produced in the iron core links not only with the secondary winding but also with the primary winding and produces a self-induced emf in the primary coil itself. This induced emf opposes the applied voltage as per Lenz’s Law and so, this emf is sometimes called Back emf.

Related Posts